Creative concept and photography: Rosina Pencheva

Text: Maria Boncheva

Original designs by Getz, including prototypes for international pipe clubs, a 15-year anniversary pipe (right, middle), a pipe designed by his daughter – shape and inlay drawings (bottom left)

Solo exhibition, Brave Creation, Sofia, September 2022

Design inspired by the Native American pipe, solo exhibition, Brave Creation, Sofia, September 2022

Solo exhibition, Brave Creation, Sofia, September 2022

Classic Canadian model with a rustic finish, solo exhibition, Brave Creation, Sofia, September 2022

Solo exhibition, Brave Creation, Sofia, September 2022

A project of two pipes created for Getz's colleague and friend – the engraver Anton Marinov and his wife. The models are an eloquent example of a combination of smooth and sandblasted finish.

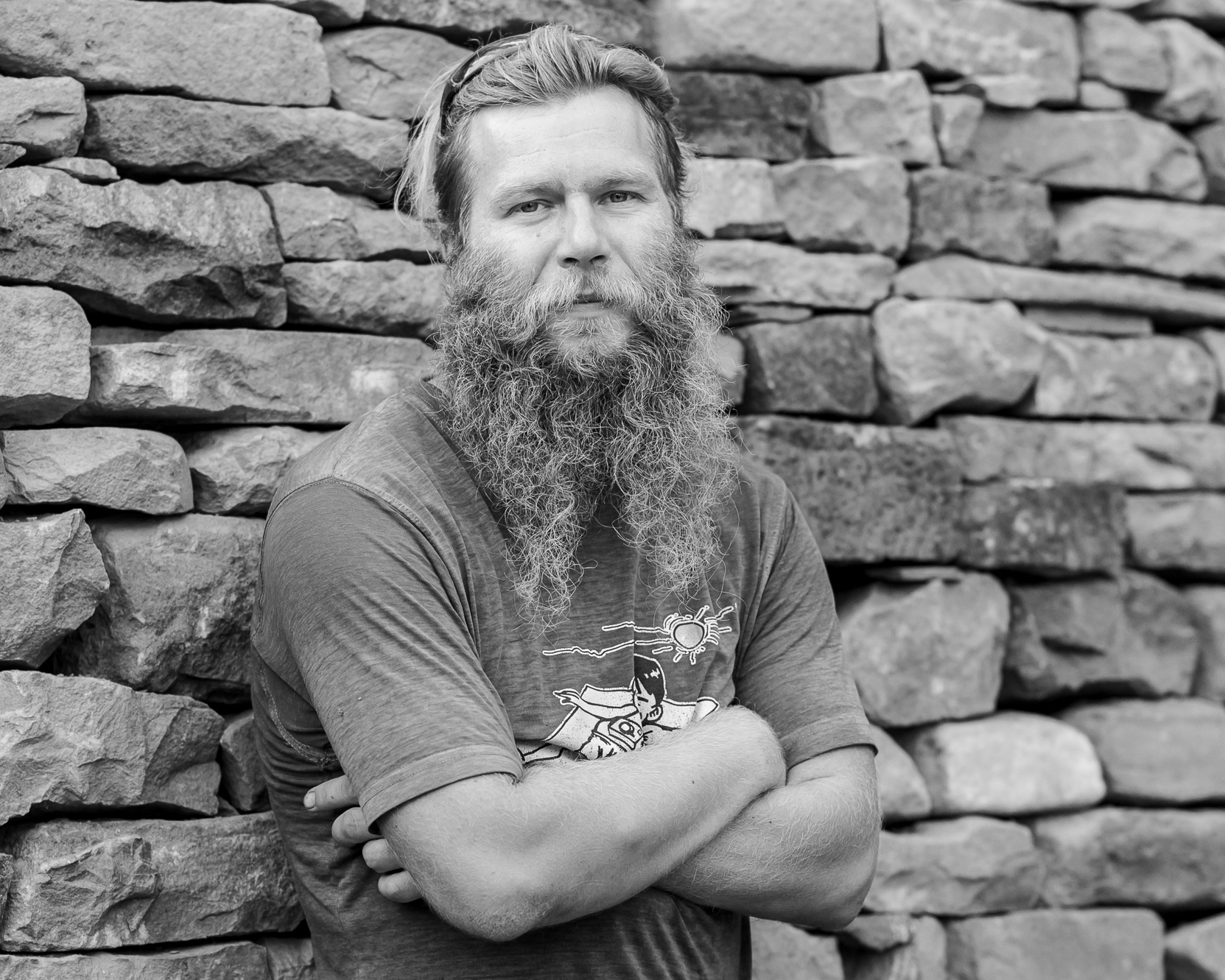

The most challenging and special project in Getz's practice is for a scuba diver client. The pipe he crafted in 2018 is a prototype of the iconic Mark V Normobaric Heavy Diving Helmet. The preparation for crafting this tobacco pipe took Getz nearly two months, during which he researched, sketched, and selected appropriate parts – clockwork elements, parts of water taps, brass works and other "whirlpools". The functioning pipe contains a total of over 100 parts.

Spare parts for the tobacco pipe – a prototype of the iconic Mark V Normobaric Heavy Diving Helmet model made by Getz in 2018

Tobacco pipe – a prototype of the iconic Mark V Normobaric Heavy Diving Helmet model made by Getz in 2018

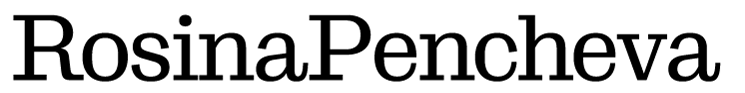

"Pipe making blends perfectly the skills, aesthetic views and my own pursuits as an artist." says Getz

"To some extent, I am self-taught, although I have the respective education, and was trained both technically and in art."

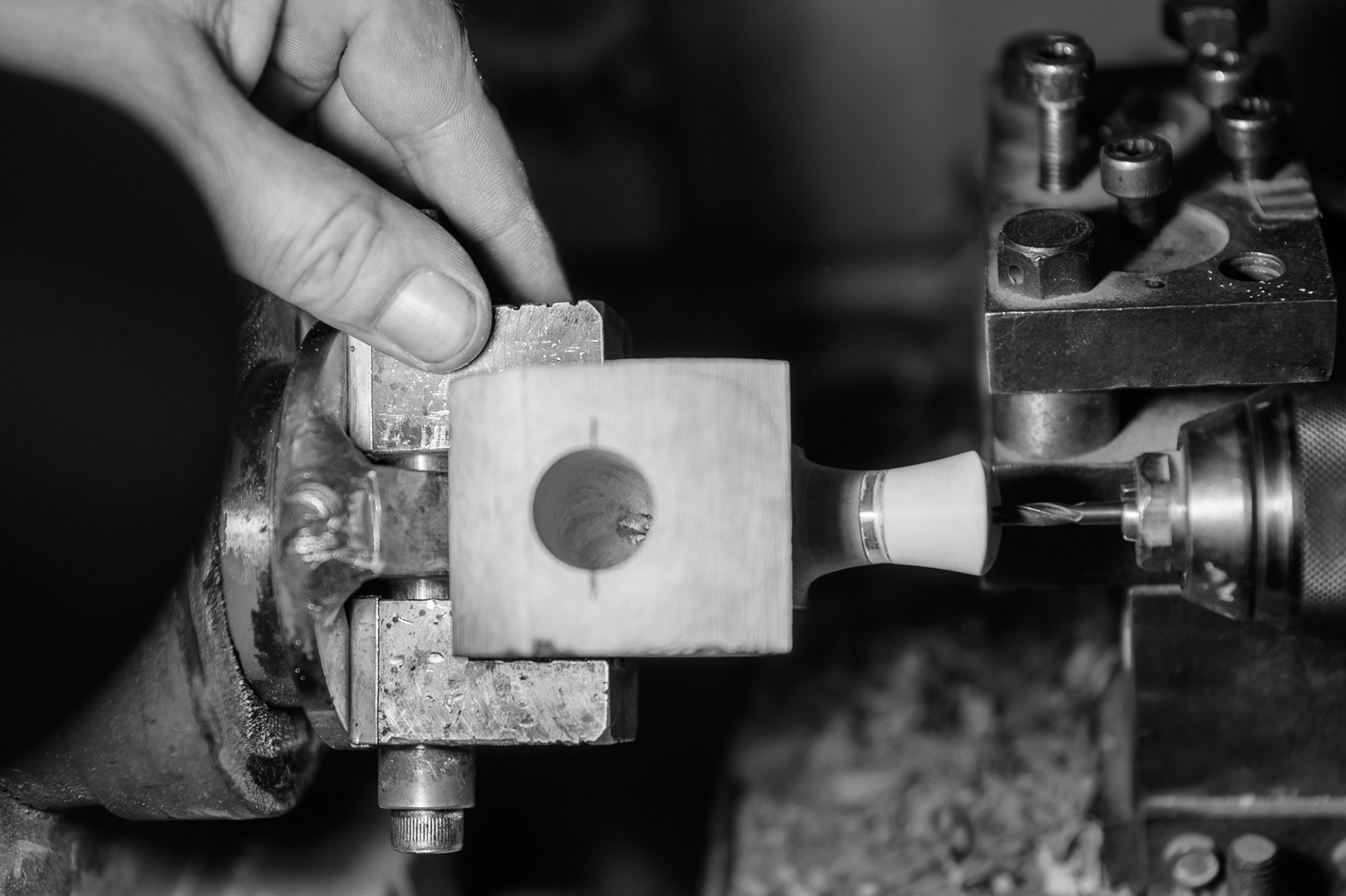

Miniature routers are part of Getz's toolkit

A multi-wall pipe with a horn-like curve in the process of intermediate pickling. The purpose of this stage of production is to enhance the contrast of the pattern of the wood itself.

Finished tobacco pipes and some in progress, along with briar wood blocks and Getz sketches

Stage of Getz's conceptual project – interpretation of the so-called pocket pipe model where the mouthpiece is rotated towards the head and this makes it compact.

Type of metal stamps with which Getz marks his crafted pipes and thus "signs" them for authorship

Pipes with the so-called second cooling chamber (reverse calabash)

Opening of the second cooling chamber (reverse calabash)

“As early as a child, I already made scale models of cars, and airplanes from wood. This took me to the High School of Art in Kazanlak.”

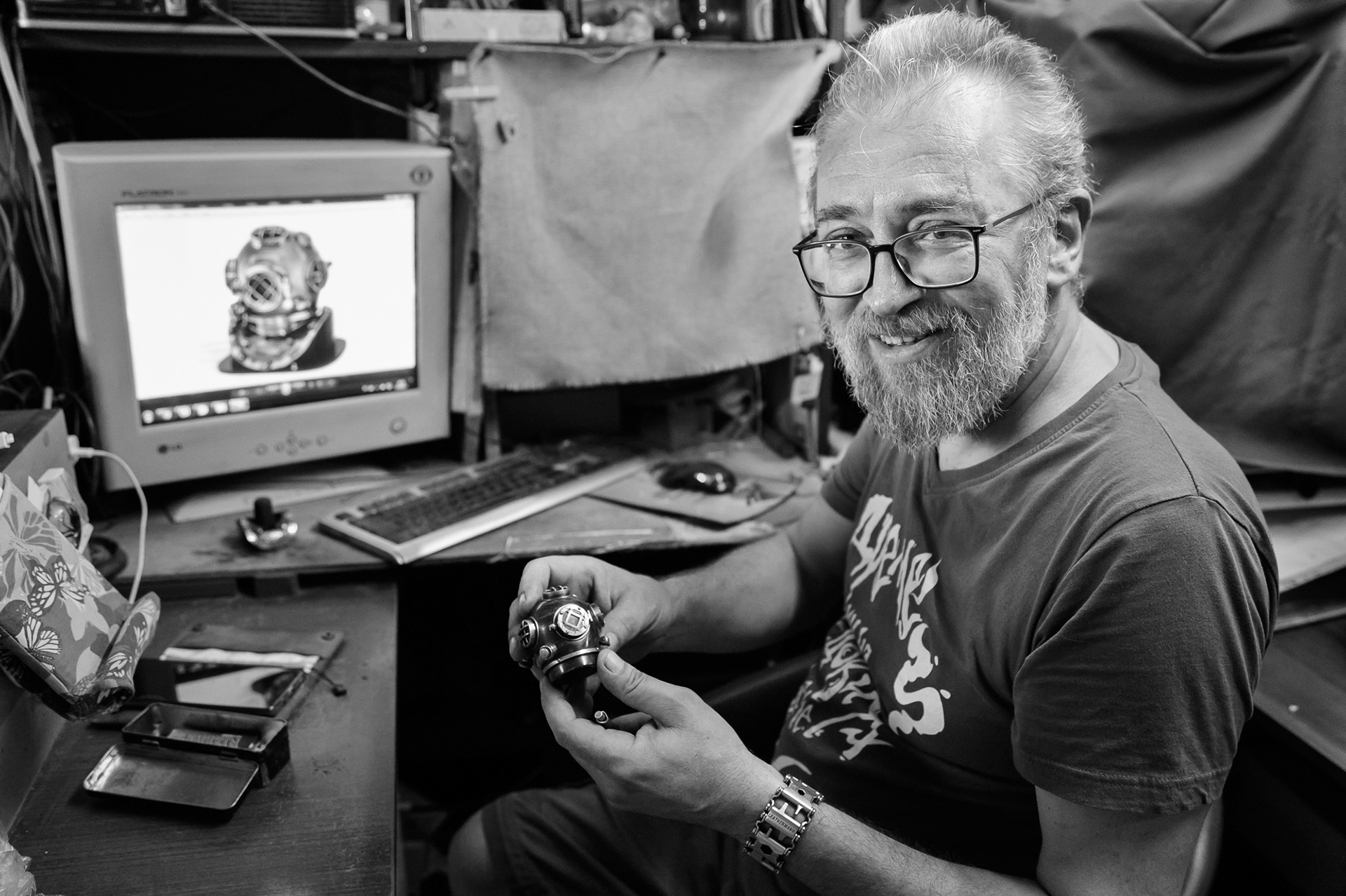

Filing the mouthpiece to make it flat

I do not have a teacher proper. For ten years or so after the beginning, I worked actively with a Czech master, however it was more about partnership and exchange, because I had already gathered a decent speed.